Employee Evaluation in Manufacturing – How to Do It Effectively with the Skill Matrix?

Modern industrial manufacturing is much more than repetitive tasks on an assembly line. It’s a complex ecosystem where each employee plays a crucial role in efficiency, quality, and workplace safety. That’s why production employee evaluation must be systematic, fair, andModern industrial manufacturing is much more than repetitive tasks on an assembly line. It’s a complex ecosystem where each employee plays a crucial role in efficiency, quality, and workplace safety. That’s why production employee evaluation must be systematic, fair, and based on concrete data. The SkillBox Skill Matrix provides an effective solution for this challenge.

Why Is Employee Evaluation In Manufacturing So Important?

In manufacturing, every piece of the puzzle—people, machines, processes—must work precisely. Only then can organizations achieve operational and financial goals. Employee evaluation is not just a control tool but primarily strategic support for organizational development. Employee competencies have a direct impact on product quality, line productivity, and workplace safety.

Key competency areas include:

- Knowledge of safety procedures

- Machine and equipment operation skills

- Compliance with quality standards

- Teamwork and independence

- Flexibility in job rotation

Without an organized system, all these elements risk being evaluated subjectively, which can cause inequality and poor HR decisions. The implementation of a tool like the SkillBox Skill Matrix is therefore essential for objective, repeatable, and transparent evaluation.

Common Mistakes in Employee Evaluation In Manufacturing

For evaluations to be effective and fair, they must be founded on reliable criteria and actual job performance, not intuition or personal preferences. Common mistakes include:

- Basing ratings on supervisors’ subjective feelings

- Lack of uniform standards (different criteria among managers)

- Ignoring technical skills or focusing only on behavior or attendance

- Rushed or superficial assessments

- Reluctance to provide critical feedback

- Lack of documentation or outdated competency data

Avoiding these pitfalls requires a transparent system with a process that clearly specifies what is being evaluated and how—regardless of experience or personal relationships.

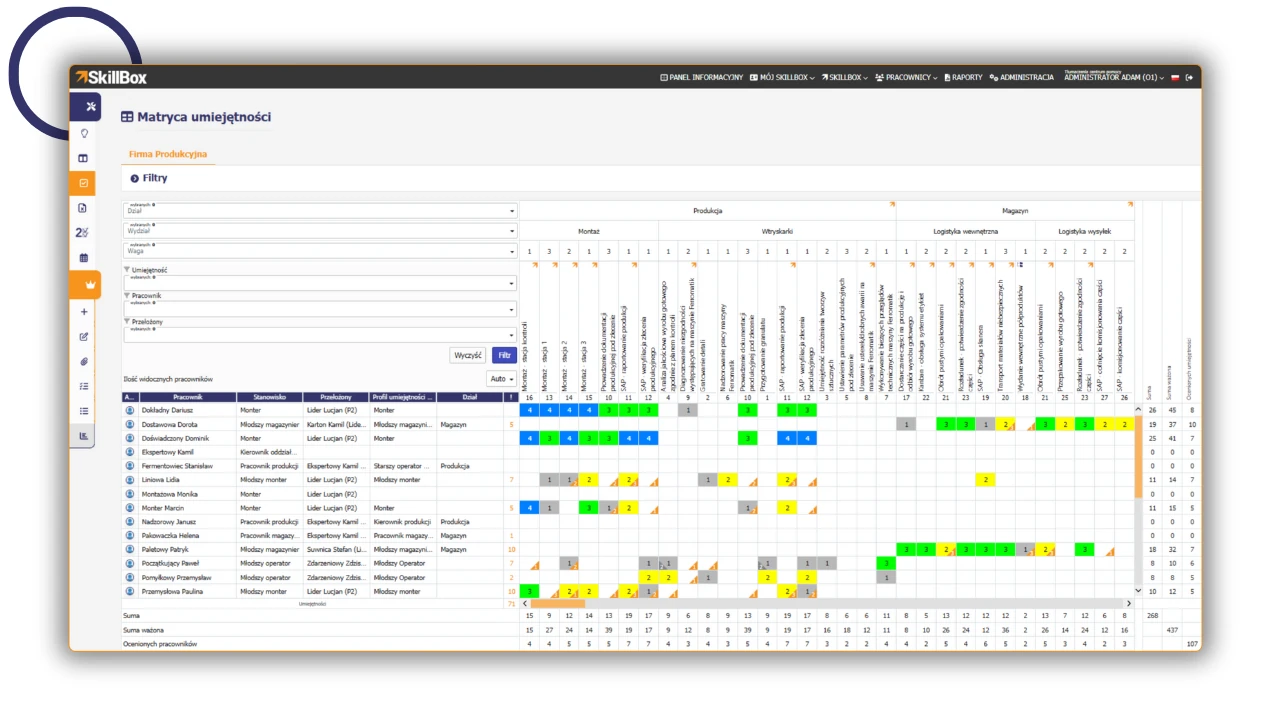

SkillBox Skill Matrix – What Is It?

The SkillBox Competency Matrix lets you manage skills at the team or organizational level. It maps each team member’s skills, allowing quick assessment, identification of knowledge gaps or redundancies, and facilitates planning for employee development. The system enables custom scales, multiple matrices, and visual summaries that make HR decisions easier.

Benefits for Manufacturing Companies

Using a Skill Matrix results in:

- Rapid identification of skill gaps

- Objective and transparent competency assessment

- Support in planning training and employee development

- Better task allocation

- Progress monitoring

- Reduced operational risk

- Increased employee motivation

With up-to-date competency data, you can more efficiently assign employees to production tasks, monitor their development, and respond to operational risks.

Practical Skill Matrix Use Cases

- Creating Skill Profiles: Useful if employees in the same position have different tasks.

- Visualizing Skills: Helps identify bottlenecks, where reliance on a single employee could stop production.

- Example 1 (CNC Operator): If John is rated 3/4 on CNC operation while others are at 1 or 2, he becomes a mentor, and less-experienced staff need training.

- Example 2 (Packer): Anna scores 4/4 in packing when only 3 is required—she’s a candidate for promotion or redeployment.

- Example 3 (Warehouse Worker): Michał, despite tenure, has low competence in the new WMS system—he needs targeted training.

Linking Job Duties and Evaluation Criteria

In order for the evaluation of a production worker to be fair and, moreover, of value to the organization, it must be directly related to his or her actual responsibilities. It is the precise definition of what is expected of a position that allows for a fair, as well as measurable comparison of the competencies of the people employed. The SkillBox platform allows you to create individual skill matrices that are closely correlated with job descriptions in a manufacturing organization.

The most common competency areas assigned to manufacturing positions

- Operating machines as well as equipment – includes the ability to safely start, stop and set machine parameters. SkillBox allows you to indicate exactly which types of machines an employee should be able to work with and at what level of proficiency.

- Maintenance of cleanliness and adherence to health and safety standards – adherence to safety rules is the foundation of working on the shop floor. The matrix can assess, among other things, knowledge of emergency procedures, use of personal protective equipment or the ability to identify potential hazards.

- Reporting on work performed – more and more companies are requiring employees to be able to use MES systems or simple reporting forms. Evaluation here includes, among other things, accuracy, timeliness and consistency of reports with reality.

- Participation in continuous improvement activities (Kaizen, 5S, TPM) – modern manufacturing plants are focusing on developing a culture of improvement. SkillBox allows the matrix to include such elements as activity in submitting ideas, participation in workshops or implementation of Lean tools.

- Adherence to quality standards – it’s not only about controlling one’s own work, but also knowing technical documentation, identifying errors and responding properly to non-conformities.

- This clarity increases acceptance and motivation and streamlines team development planning.

Thanks to such a detailed structure of the matrix, each employee is evaluated according to clearly defined and understandable criteria, rather than general, often subjective impressions of the supervisor. This, in turn, influences greater acceptance of the evaluation results, increases motivation and facilitates strategic planning for the development of the production team.

The Role of the Production Leader in Competency Evaluation

We wrote about the role of the production leader in the process in the context of the matrix in our series “Toolbox – Skills Matrix in Practice.” The principle of operation at the source is that supervisors should have a part in the development of skills and evaluation. Why?

Leaders, foremen and masters, have unique knowledge of their team. They play an important role in the appraisal process they are the ones who observe the work of the team, verify progress and are best able to assess an employee’s real competence. SkillBox supports shift leaders and champions by providing them with clear, understandable tools for conducting evaluations.

Instead of intuitive “eyeballs,” the leader sees specific indicators: who knows a certain procedure, who can operate a certain machine, who is certified, and who is running out of training. As a result, leaders not only better manage task rotation, but also more consciously support the development of their people.

Manage your competencies in a planned manner and schedule a no-obligation consultation SkillBox Competency Matrix.

Periodic evaluation of production employees

The periodic appraisal system allows full integration with the Skills Matrix. This means that the annual or semi-annual appraisal interview is based on data from the matrix, competency levels, progress, completed training or changes in job profile. As a result, the manager does not evaluate “off the top of his head,” but uses hard data.

In addition, SkillBox automates assessment reminders and enables the creation of electronic reports for HR or management. Thanks to this, the periodic evaluation of a production employee is not just a necessity to tick off, but becomes an added value that really supports and motivates employees. The SOOP module together with the matrix allows us to look at the employee in a holistic way. In the HR system, we can assess soft competencies, skills, the degree to which goals are being met, as well as examine training needs.

Plan Your Employee Evaluation In Manufacturing

In the Industry 4.0 era, flexibility, quality, and speed of response are what count. Evaluations should rely on solid data, not gut feeling. The SkillBox Skill Matrix moves assessments from guesswork to developmental, data-driven management, letting you recognize who delivers, where to invest, and how to reduce operational risk.

If you want to better utilize your manufacturing team’s potential, switch to data-driven evaluation with the SkillBox Competency Matrix.

You may be interested in:

How the Succession Matrix Protects Workforce Security

Document Workflow in a Company – How to Streamline Processes with an Electronic System?

DO YOU WANT TO KNOW MORE?

We have a gift for you!

You can test managing of human capital with professional Competency Matrix in spreadsheet.